building glass blocks

| Katunduyo: | building glass blocks | ||||||

| Nambala ya Model: | PARALLEL | ||||||

| Zakuthupi: | Glass | ||||||

| size: | 190x190mm

|

||||||

| Makulidwe: | 80mamilimita | ||||||

| Manyamulidwe: | 5~ 10days otsogolera nthawi. Ndi chombo,DHL / TNT / FedEx kufotokoza, katundu wonyamula ndege etc.. | ||||||

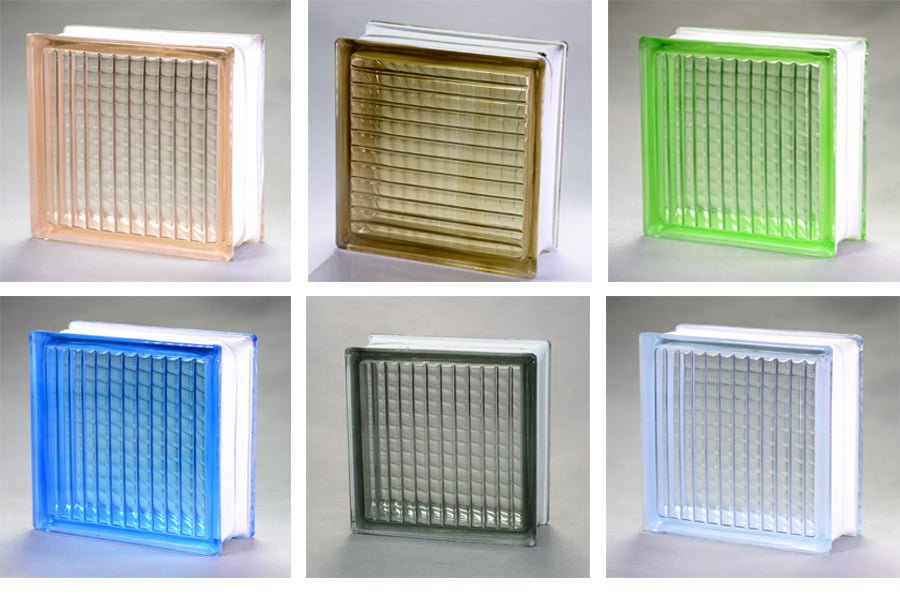

| Colour: | Buluu, green, gray, brown, wofiira, clear, ndi zina. | ||||||

| Kutumiza & Utumiki: | Kutumiza kwanthawi yake nthawi iliyonse. Provide reliable service . Provide construction suggestions and solutions. Cholinga chathu ndikukwaniritsa kasitomala aliyense ndi ntchito yabwino kwambiri. | ||||||

| Mtengo wa MOQ | 1000piece | ||||||

| Phukusi | Standard cartons packing 6piece/cartons; 14KG/cartons;0.19CMB; 1530cartons(9180piece)/container. Or with pallet |

||||||

|

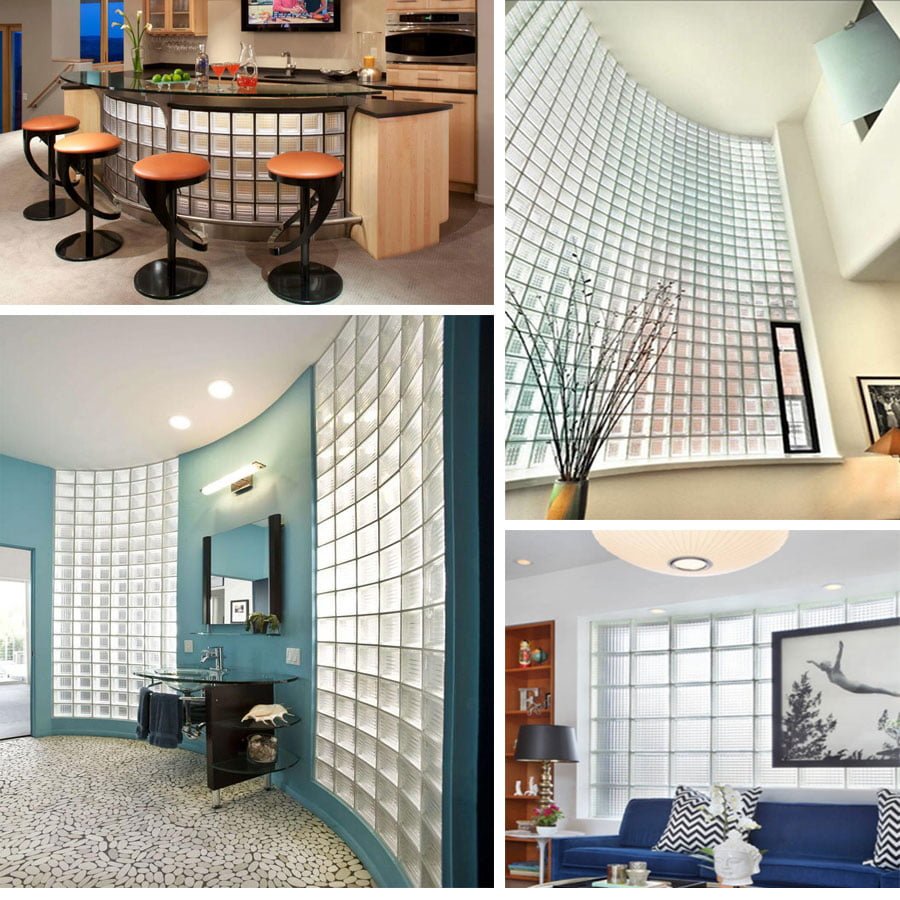

Kugwiritsa ntchito |

|

||||||

Makasitomala mlandu:

Elated Products:

UPHINDO WATHU:

Tili ndi zokumana nazo zambiri pakugulitsa m'bwalo ndipo timadziwa zambiri zamalonda.

We can provide different kinds of buying services like sourcing, QC checking,containers loading and so on.

FAQ:

A: How to produce? Production Process?

B:There are two production methods, namely welding and bonding.

1. The welding process is as follows:

Raw material mixing→melting→cutting→pressing half blank→welding→annealing→inspection→painting→packaging

2.Bonding method

Inserting the side walls of the two concave half glass bricks into the grooves of the thermoplastic plastic ring member with the H-shaped section, and by means of the sealing material, the surface of the profile is softened under the action of temperature and extrusion, thereby The concave half-piece glass bricks are firmly bonded together to form an integral hollow glass brick.

Compared with the welding method, the bonding method has low cost and accurate product size, but the strength is far lower than that of the welding method.

A: Use of this product?

B: Usually room space do not want to have a dark room (light room no) occurs, even if the walkway also desirable to have light. The use of glass bricks not only has the function of partitioning, but also leads the light into the inside, and has good sound insulation effect. Glass bricks can be applied to exterior walls or indoor spaces to provide good daylighting and a sense of continuity. Whether it's a single inlay or a whole wall, it's a finishing touch.

The glass brick is applied to the outer door to bring natural light and outdoor scenery into the room. The brick has high strength and durability, can withstand the wind attack, and can ensure safety without additional maintenance structure.

A: How construction?

B:first is mortar preparation (according to white cement: fine sand: building glue: water = 10:10:0.3:3 ratio), then install the positioning bracket ("+" type or "T" type or "L" mtundu) and use The mortar bricks remove the excess plates on the positioning bracket. First use a greasy knife to sew and remove excess mortar. After removing the mortar, the glass brick can be formed.

▲You can also prepare the "+" fixed spacer frame and the horizontal wood chips (width about 5cm, thickness not more than 0.4cm) for the level of the planned construction, make the wooden frame, blend the special adhesive, and brush Evenly. Starting from the corner below the frame, the blocks are made of glass bricks. Be sure to place the fixed spacers at the four corners.

Remove the outer leakage portion of the fixed spacer frame and remove excess adhesive from the gap. After 8 to 12 hours of adhesive drying, different colors of silicone rubber can be injected into the gap of the glass brick to increase the structural strength.

Malangizo azinthu